Emergency Electrical Repairs: How to Minimize Downtime in Industrial Settings

In industrial facilities, electrical failures can bring operations to a standstill, resulting in production delays, financial losses, and potential safety hazards. Whether it’s a power outage, motor failure, short circuit, or electrical panel malfunction, every minute counts when dealing with emergency electrical repairs.

To keep operations running smoothly, facilities must have a proactive strategy to address electrical emergencies quickly and efficiently. In this article, we will explore the most common industrial electrical emergencies, strategies to minimize downtime, and how Bullet Trade Services provides expert emergency electrical repairs across Ontario.

Common Industrial Electrical Emergencies

Industrial facilities rely on high-voltage electrical systems, automation, and control panels to maintain operations. When an emergency occurs, rapid troubleshooting is essential to prevent extended downtime. Here are some of the most frequent electrical issues in industrial settings:

1. Power Outages and Electrical Failures

Unexpected power failures can halt production and damage sensitive equipment. Causes may include:

- Utility grid failures

- Overloaded circuits

- Transformer malfunctions

- Faulty electrical panels

2. Motor and Drive Failures

Electric motors power industrial machines, conveyors, and pumps. Overheating, voltage imbalances, or worn-out components can lead to sudden failures, impacting production.

3. Circuit Breaker Trips and Short Circuits

Overloaded circuits or damaged wiring can cause frequent breaker trips, leading to power disruptions and safety risks.

4. Equipment Overheating and Electrical Fires

Overloaded electrical panels, damaged wiring, or faulty insulation can cause overheating, increasing the risk of electrical fires and system damage.

5. Automation and PLC System Malfunctions

Programmable Logic Controllers (PLCs) control automated systems, but electrical surges, software failures, or faulty sensors can cause machinery to malfunction or stop working.

6. Grounding and Electrical Shock Hazards

Improper grounding can lead to electrical shocks, system malfunctions, or power fluctuations, posing serious safety risks to workers.

How to Minimize Downtime During Electrical Emergencies

When an electrical failure occurs, facilities must act quickly and efficiently to restore operations. Here’s how to minimize downtime and prevent costly disruptions:

1. Have an Emergency Electrical Response Plan

Every facility should have a clear action plan for handling electrical failures. This should include:

- A designated response team trained to manage electrical emergencies

- Emergency shutdown procedures to prevent damage to equipment

- A list of on-call industrial electricians for rapid response

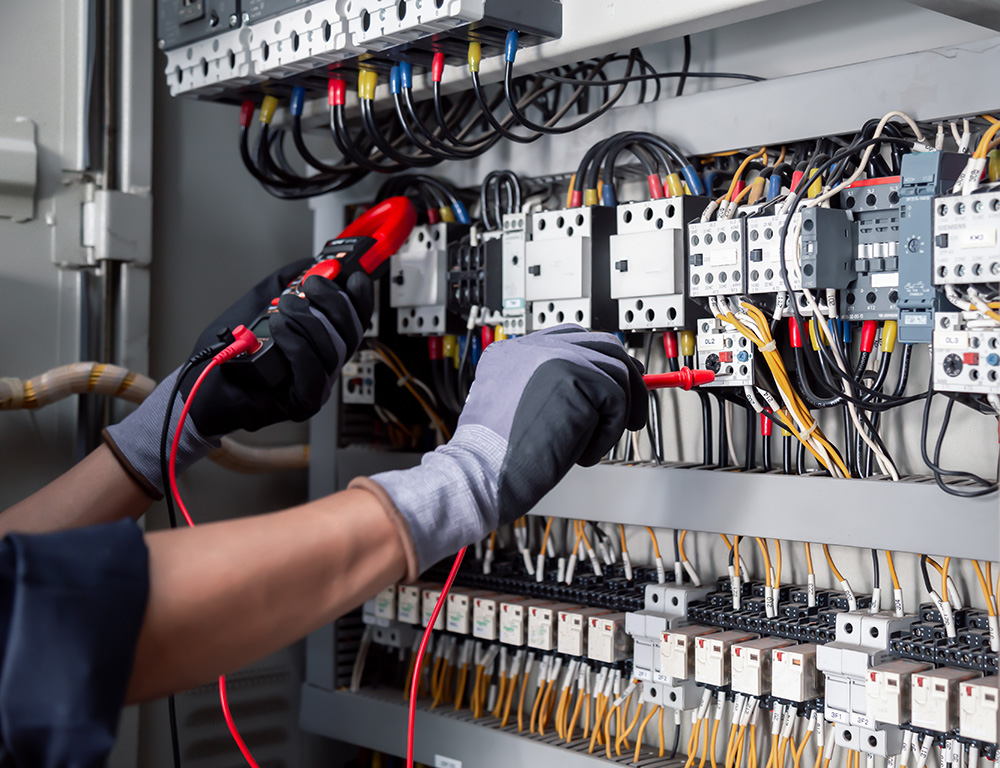

2. Perform Rapid Troubleshooting

Quickly identifying the root cause of an electrical failure can reduce repair time. Key troubleshooting steps include:

- Checking electrical panels for tripped breakers or blown fuses

- Inspecting power distribution systems for faults or overloads

- Using infrared thermography to detect overheating components

- Testing circuit continuity to locate wiring issues

3. Maintain Backup Power Solutions

Having backup power systems, such as generators or uninterruptible power supplies (UPS), can prevent data loss and allow for safe shutdowns during outages.

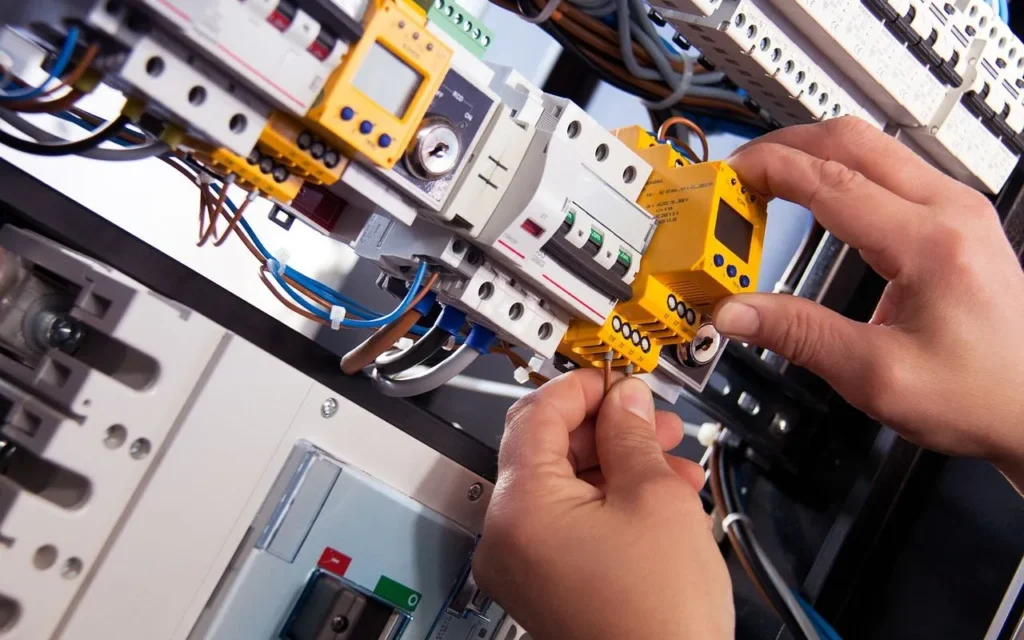

4. Schedule Regular Electrical Maintenance

Preventive maintenance is the best way to avoid emergency failures. Facilities should:

- Inspect and clean electrical panels regularly

- Test motor and drive systems for signs of wear

- Replace aging wiring and components before failure occurs

- Conduct thermal imaging scans to detect hotspots in electrical systems

5. Partner with a Reliable Emergency Electrical Repair Service

Working with a trusted industrial electrical contractor ensures that emergency repairs are handled quickly and professionally.

Bullet Trade Services: Your Trusted Partner for Emergency Electrical Repairs

When an electrical failure threatens your operations, you need expert electricians who can respond quickly and restore systems with minimal disruption. Bullet Trade Services offers 24/7 emergency electrical repair services across Ontario, ensuring that your facility remains productive and safe.

Why Choose Bullet Trade Services for Emergency Electrical Repairs?

✅ Rapid Response Times – Our team is available 24/7 to provide fast and efficient emergency electrical support.

✅ Highly Skilled Industrial Electricians – We specialize in troubleshooting, repairing, and upgrading industrial electrical systems.

✅ Comprehensive Electrical Solutions – From motor repairs and panel replacements to automation troubleshooting, we handle it all.

✅ Advanced Diagnostic Tools – We use thermal imaging, voltage testers, and power analyzers to quickly identify and resolve issues.

✅ Commitment to Safety & Compliance – Our electricians follow all Ontario Electrical Safety Code (OESC) standards to ensure compliance.

Our Emergency Electrical Repair Services Include:

🔧 Power restoration and electrical panel repairs

🔧 Motor and drive troubleshooting and replacements

🔧 PLC and automation system repairs

🔧 Short circuit and electrical fire damage repairs

🔧 Overloaded circuit and wiring inspections

Industrial Electrical Repair Services

Electrical emergencies in industrial settings can lead to major disruptions, safety risks, and costly repairs. By implementing a proactive emergency response plan, performing regular maintenance, and working with a trusted electrical contractor, facilities can minimize downtime and ensure continuous operations.

At Bullet Trade Services, we specialize in fast, efficient, and professional emergency electrical repairs, keeping your facility running at peak performance.

Need emergency electrical repairs? Contact Bullet Trade Services now for 24/7 support!