Common Electrical Issues in Factories and How to Troubleshoot Them

Electrical systems are the backbone of industrial operations, powering everything from production lines and machinery to automation systems and facility lighting. However, with continuous operation and heavy electrical loads, factories often experience electrical issues that can lead to downtime, equipment failure, and safety risks.

Understanding common electrical problems and their troubleshooting techniques can help facilities prevent costly disruptions and ensure smooth operations. In this article, we explore the most frequent electrical issues in factories and how to effectively identify, troubleshoot, and resolve them.

1. Power Surges and Voltage Fluctuations

Problem:

Power surges occur when there is a sudden spike in electrical voltage, which can damage sensitive equipment, disrupt production lines, and shorten machine lifespan. Voltage fluctuations, on the other hand, can cause motors and automation systems to behave unpredictably.

Troubleshooting Steps:

- Check Power Sources: Ensure your facility is receiving consistent power from the utility grid.

- Inspect Transformers and Power Lines: Loose connections, damaged insulation, or aging infrastructure can contribute to surges.

- Install Surge Protectors and Voltage Regulators: These help stabilize voltage levels and protect sensitive equipment.

- Monitor Power Loads: Overloaded circuits can lead to voltage drops and fluctuations. Redistribute power loads if necessary.

2. Overloaded Circuits

Problem:

Factories often add new machinery or increase production demands without assessing circuit capacity. Overloading a circuit can cause breakers to trip, overheating, or even electrical fires.

Troubleshooting Steps:

- Identify High-Demand Equipment: Determine which machines are drawing the most power and assess whether circuits can handle the load.

- Use Dedicated Circuits for Heavy Equipment: High-powered machinery should have separate electrical circuits to prevent overload.

- Upgrade Electrical Panels if Needed: If circuits frequently trip, it may be time to increase capacity or install additional panels.

- Regularly Inspect Electrical Panels: Check for burn marks, overheating wires, or buzzing sounds, which indicate an overloaded system.

3. Faulty Wiring and Loose Connections

Problem:

Over time, factory wiring can degrade, loosen, or become damaged due to vibrations, moisture, or overheating. Faulty wiring can lead to short circuits, equipment malfunctions, and safety hazards.

Troubleshooting Steps:

- Perform Routine Inspections: Look for exposed wires, melted insulation, or loose terminal connections.

- Tighten Electrical Connections: Loose connections can create sparks and overheating, leading to equipment failure.

- Replace Old or Damaged Wiring: If wiring appears brittle or corroded, replace it to prevent system failures.

- Use Thermal Imaging Cameras: This helps identify hotspots where wiring issues may exist before they become major failures.

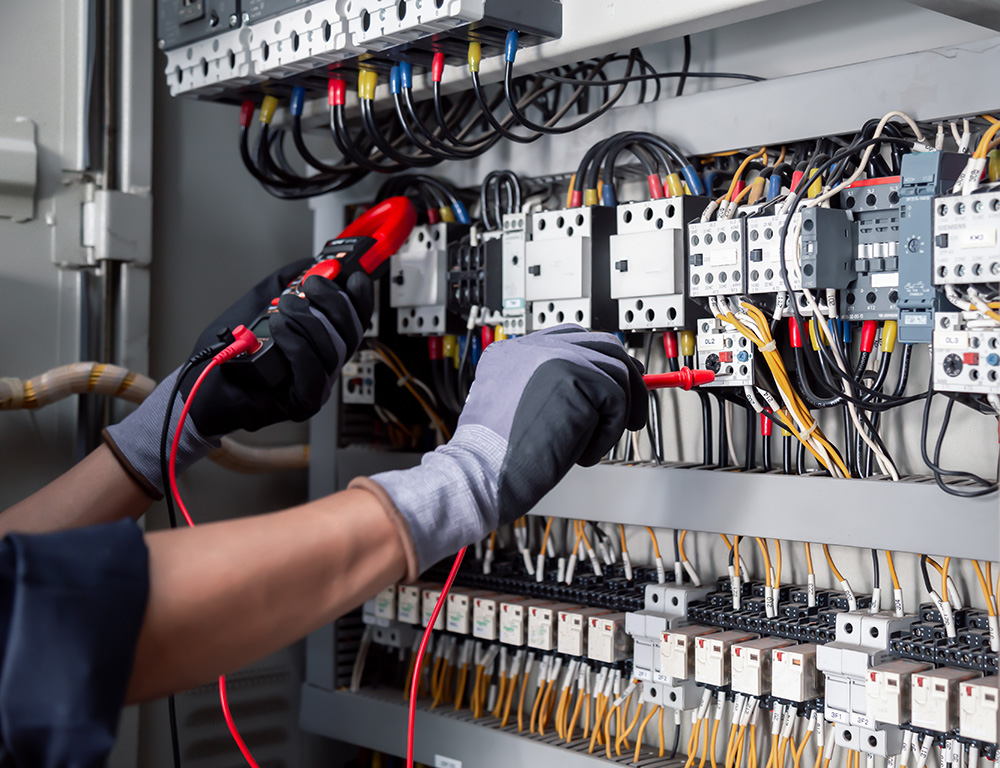

4. Electrical Panel Malfunctions

Problem:

Electrical panels distribute power throughout the facility, but issues like aging components, loose breakers, or damaged wiring can cause power disruptions.

Troubleshooting Steps:

- Check for Tripped Breakers: Reset any tripped breakers, but if they keep tripping, investigate the root cause (e.g., overload or short circuit).

- Inspect Panel Components: Look for burn marks, unusual smells, or buzzing noises, which indicate component failure.

- Schedule Preventive Maintenance: Regular panel inspections help detect issues before they cause major outages.

- Upgrade Outdated Panels: If a panel is frequently failing or unable to support new equipment, upgrading to a higher-capacity system may be necessary.

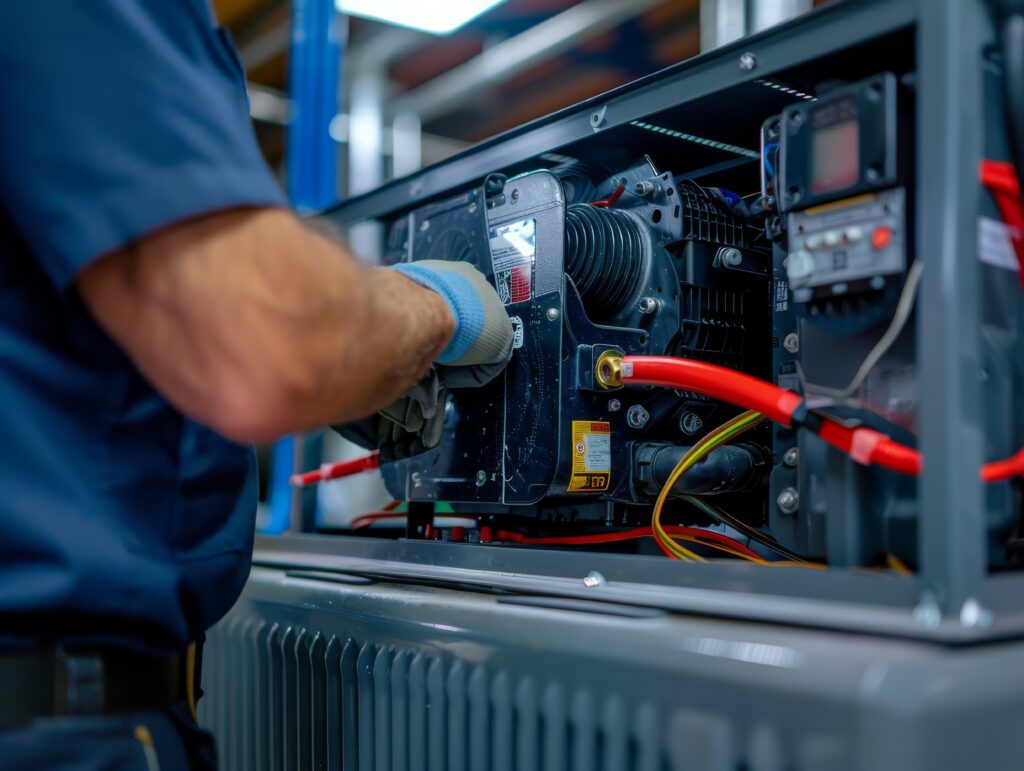

5. Motor and Drive Failures

Problem:

Electric motors and variable frequency drives (VFDs) are essential in factory automation. Excess heat, poor ventilation, electrical imbalance, or sudden stops can lead to motor burnouts and drive failures.

Troubleshooting Steps:

- Monitor Temperature and Ventilation: Motors should be kept cool and have proper airflow.

- Check Voltage Balance: Uneven voltage supply can cause overheating and shorten motor lifespan.

- Inspect Bearings and Wiring: Worn bearings or frayed wiring can lead to motor inefficiencies and unexpected shutdowns.

- Use Predictive Maintenance Tools: Vibration analysis and infrared scanning can help detect early signs of failure.

6. Automation and PLC Malfunctions

Problem:

Programmable Logic Controllers (PLCs) and automation systems rely on stable electrical signals to function. Interference, wiring issues, or software failures can disrupt production processes.

Troubleshooting Steps:

- Check Power Supply to PLCs: Ensure PLCs are receiving consistent voltage without spikes.

- Inspect Input/Output Connections: Loose or damaged connections can lead to erratic machine behavior.

- Use Shielded Cables to Prevent Interference: Electromagnetic interference (EMI) can disrupt signals, especially in high-power environments.

- Update PLC Software and Firmware: Outdated or corrupted software can cause automation failures.

7. Electrical Grounding Issues

Problem:

Improper grounding can cause electrical shocks, unstable power flow, and even equipment damage.

Troubleshooting Steps:

- Test Grounding Connections: Ensure that all machines and panels are properly grounded.

- Check for Corroded or Loose Ground Wires: Poor grounding can cause voltage fluctuations and safety risks.

- Use Ground Fault Circuit Interrupters (GFCIs): These prevent shock hazards by detecting and cutting off faulty currents.

- Follow Industrial Electrical Codes: Ensure compliance with Ontario Electrical Safety Code (OESC) requirements.

Preventive Maintenance: The Best Solution for Electrical Issues in Factories

The best way to avoid electrical failures in factories is through regular preventive maintenance and system monitoring. Bullet Trade Services provides expert industrial electrical services, ensuring that electrical systems remain efficient, safe, and reliable.

How Bullet Trade Services Can Help

✅ Comprehensive Electrical Inspections – Identifying and fixing potential issues before they cause major failures.

✅ 24/7 Emergency Electrical Repairs – Rapid response to electrical breakdowns to minimize downtime.

✅ Preventive Maintenance Programs – Keeping electrical panels, wiring, and motors in top condition.

✅ Industrial Automation and PLC Support – Troubleshooting and upgrading automation systems for improved efficiency.

✅ Energy Efficiency Upgrades – Reducing electrical waste and lowering operational costs.

Conclusion

Electrical issues in factories can disrupt production, create safety hazards, and lead to costly downtime. By understanding common electrical problems and implementing effective troubleshooting and maintenance strategies, facilities can ensure smooth and uninterrupted operations.

At Bullet Trade Services, we specialize in industrial electrical troubleshooting, maintenance, and system upgrades, providing Ontario’s best electrical solutions.

Need expert industrial electrical services? Contact Bullet Trade Services today and keep your factory powered for success!